New York-based marketing company aims to import state-of-the-art systems to benefit the U.S. restaurant and food industry

NEW YORK (May 18, 2023) — UNIVA, a New York-based marketing company that works to expand Japanese technology systems into the U.S. restaurant and food industry, is pleased to announce they will showcase four new systems at the National Restaurant Association Show 2023.

The show runs from May 20-24 at McCormick Place in Chicago, Ill.

Billed as an event that supports the restaurant and food community through sharing information, tools and insights, the annual event remains one of the premier industry expositions. UNIVA America President Nobu Kimoto is excited to highlight some of the latest in Japanese technology.

“There is so much innovation going on in the restaurant and food industry right now across the globe, we are thrilled to be able to showcase some of the most exciting systems at the National Restaurant Association Show,” Kimoto said. “This year, we are bringing some of what we believe will be ground-breaking systems for attendees to see firsthand.”

Among the technology UNIVA will highlight is an AI-based visual inspection system.

Trackbott utilizes advanced artificial intelligence and high-resolution cameras to capture real-time footage of the production line.

Its sophisticated algorithms enable the system to identify and detect foreign objects, such as hair or plastic pieces, and missing items within the products.

Upon identification, Trackbott promptly notifies operators through visual indicators and alarms, ensuring swift action can be taken to rectify any issues.

One of the standout features of Trackbott is its AI learning function.

By continuously accumulating data on detected objects, including foreign contaminants and missing items, the system constantly refines its detection capabilities, improving accuracy over time.

This adaptive learning process empowers Trackbott to handle items with varying contents, even when the production line undergoes daily changes.

The benefits of implementing Trackbott into production lines are manifold.

Firstly, the system mitigates the risks associated with foreign object contamination, reducing the potential for costly compensation claims arising from customer complaints.

By meticulously recording all images, Trackbott provides a comprehensive audit trail for quality assurance purposes.

Additionally, Trackbott significantly improves overall production line quality by minimizing the likelihood of missing items and contamination.

Its high-speed and precise detection capabilities ensure that every product leaving the line meets the required specifications, bolstering customer satisfaction and brand reputation.

From a financial standpoint, Trackbott offers substantial cost reductions compared to manual inspections.

Operating at a fraction of the cost of employing human inspectors, the system not only enhances efficiency but also maximizes the utilization of resources.

“Trackbott represents a significant leap forward in visual inspection technology,” Kimoto said. “With its AI-powered intelligence and continuous learning capabilities, Trackbott enhances the quality control process, minimizes risks, and optimizes production line efficiency. We proudly offer this cutting-edge solution to producers seeking to elevate their quality assurance measures.”

MD302BT – Bluetooth Data Collector

The MD302BT stands out with its compact and lightweight design, allowing users to operate it with one hand while ensuring a comfortable grip.

Its ergonomic construction enhances user experience, enabling quick and efficient barcode scanning and data collection.

One of the key features of the MD302BT is its seamless data transfer capability.

Leveraging Bluetooth technology, the system enables real-time data transmission to any compatible device, eliminating the need for manual data entry or time-consuming syncing procedures.

This instantaneous data sharing enhances productivity and efficiency, empowering businesses to make informed decisions promptly.

The MD302BT is built to withstand rugged environments and demanding conditions. With a robust IP65 rating, the system is resistant to dust and splashes, ensuring reliable performance even in challenging work environments.

Furthermore, the device boasts a drop strength of 1.2 meters, providing durability and protection against accidental drops and impacts.

Convenience is at the forefront of the MD302BT’s design.

The central unit has a built-in battery, eliminating the need for constant battery replacements and allowing for uninterrupted operation.

Additionally, the device features a magnetic connector for effortless charging, ensuring a hassle-free and efficient charging experience.

The MD302BT is particularly well-suited for inventory management of ingredients, offering significant advantages in retail, restaurant, healthcare, manufacturing, and logistics industries.

By effortlessly scanning barcodes and collecting data, the system simplifies and accelerates inventory tracking, reducing human errors and improving overall accuracy.

“UNIVA America is proud to introduce the MD302BT, a game-changing solution for efficient data management,” Kimoto said.”With its compact design, real-time data transfer capabilities, and robust durability, the MD302BT empowers businesses to streamline operations, increase productivity, and make informed decisions. We believe this cutting-edge barcode system will revolutionize inventory management and data collection processes.”

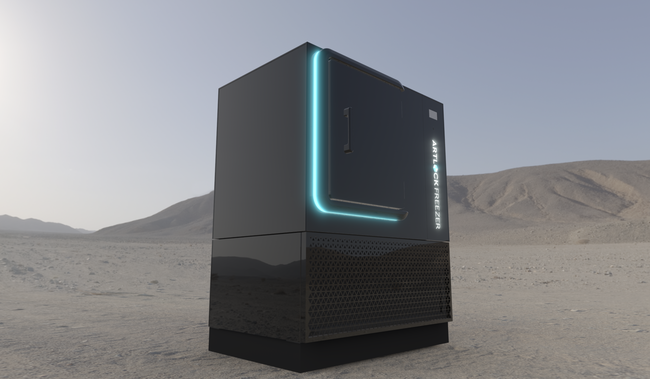

Artlock Freezer

For years, concerns about quick freezing have plagued the culinary world. Everyday worries include the inevitable deterioration of taste and quality, uneven freezing resulting in longer cooking times, and inefficient defrosting processes due to frequent frost formation.

After a decade of relentless research and development, a Japanese manufacturer, Daybreak Co, Ltd, has successfully developed a unique freezing method that revolutionizes preserving ingredients without causing damage.

The Artlock Freezer incorporates the ground-breaking “micro-wind system,” which ensures high-quality cooling throughout the freezing process.

By surrounding the food with cold air of -35℃ or lower, this innovative method forms small and uniform ice crystals, preserving the integrity and taste of the ingredients without compromising their quality.

Another remarkable feature is the “anti-frost mechanism,” enabling continuous operation and significantly improving productivity.

With no frost build-up inside the freezer, there is no need for time-consuming defrosting work.

The absence of frost formation ensures uninterrupted cooling efficiency, allowing for optimal preservation and reducing unnecessary downtime.

The Artlock Freezer is equipped with a “freeze protection” system, utilizing advanced sensors to automatically detect crucial information such as internal temperature, ambient temperature, and operating pressure.

This efficient operation prevents breakdowns and maintains precise refrigeration quality, ensuring the longevity and performance of the freezer.

Further, the freezer boasts the “Smart Freeze” feature, which automatically adjusts the freezing settings to the optimal conditions based on the characteristics of the ingredients.

Whether adding hot ingredients or freezing items at different times, the Artlock Freezer guarantees stable frozen quality, maintaining the taste, aroma, and texture without limitations.

“Artlock Freezer represents a new era in freezing technology,” Kimoto said. “With its innovative freezing method, this high-quality freezer ensures that food retains its original flavors and textures, increasing shelf life and providing a superior culinary experience. We are excited to bring this cutting-edge appliance to kitchens worldwide.”

Suzakiva Gosanvaki Castella Cake

The name “Gosanyaki Castella” derives from its unique baking process, where egg yolk and egg white are meticulously combined at a ratio of 5:3 rather than the customary 5:5.

This distinctive technique demands a higher skill level, resulting in a cake of unparalleled taste and texture.

The meticulous process involves creating a foam-like consistency through diligent mixing and expertly manipulating the temperature during baking, raising and lowering it continuously.

Today, only a handful of individuals in Nagasaki prefecture in Japan possess the expertise required to bake an authentic Gosanyaki Castella.

The Suzakiya Gosanyaki Castella Cake represents the epitome of craftsmanship and culinary excellence.

Each cake is a testament to the dedication and artistry of the bakers, meticulously crafting a dessert that is visually stunning and delights the taste buds with its unique flavor profile and delicate texture.

“We are thrilled to bring the Suzakiya Gosanyaki Castella Cake to the U.S. market,” Kimoto said. “This remarkable delicacy showcases the artistry and skill of Nagasaki’s finest bakers, who have mastered the intricate process of creating a Gosanyaki Castella. We are excited to share this culinary treasure with American consumers, allowing them to experience a truly extraordinary dessert.”

***

For more information about the National Restaurant Association Show 2023, visit their website, nationalrestaurantshow.com.

For more information about UNIVA America, Inc. ,visit their website, www.en.univaamerica.com.

Booth information of UNIVA America, Inc.: Booth #6072 (Tech Pavilion)

Onsite Contact: Nobu Kimoto / Cell phone 516-526-7365